In engineering and materials science a stress strain curve for a material gives the relationship between stress and strain it is obtained by gradually applying load to a test coupon and measuring the deformation from which the stress and strain can be determined see tensile testing these curves reveal many of the properties of a material such as the young s modulus the yield strength.

Stress strain curve for ceramics and thermosetting plastics.

The curve on the right shows a stress strain curve for a material that strain hardens.

For brittle ceramics a three point bending apparatus shown in the figure below is used determine the stress strain behavior and the measurement results are used to calculate an equivalent modulus of elasticity.

The unloading curves from different strain rate tests are nearly identical suggesting.

At point d the tensile stress and elongation at yield are determined.

ε 1 0 01 s 0 05 s ε 2 and 0 1 s ε 3.

Which of the following types of stress strain relationship best describes the behaviour of brittle materials such as ceramics and thermosetting plastics σ stress and ε strain.

With a very short elastic region but highly capable of supporting huge stresses.

A true stress true strain curves for uniaxial compression tests.

As in the previous stress strain curves there is an initial linear elastic portion followed by a deviation from linearity indicating permanent or plastic deformation.

Q is the yield point r is the uts point and s the fracture point.

14 shows the true stress true strain curve from the simulation when a 30 s delay was allotted prior to unloading.

View hint view answer discuss.

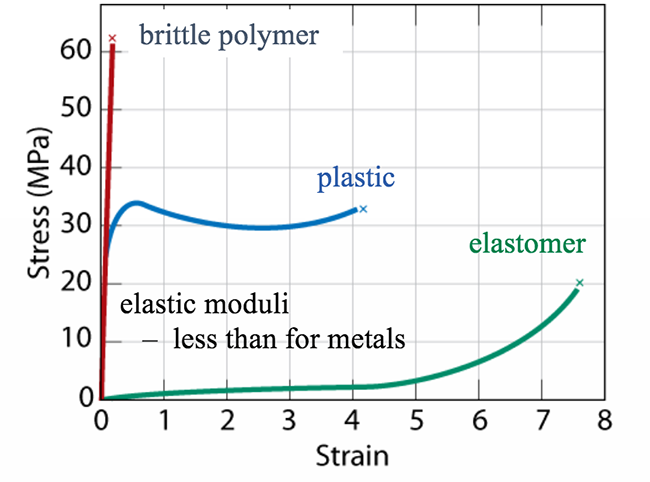

And finally analogous to ceramics are the stiff fibers and rigid plastics.

Elastomers are the ones that strains more w a lower stress.

B decompositions of the stress strain behavior into an equilibrium part and a time dependent part.

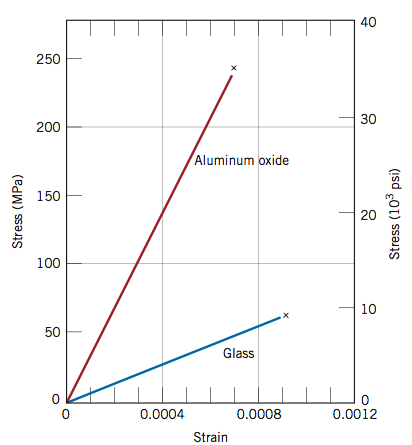

2 stress strain curve for ceramics.

A hypothetical engineering stress strain curve shown in the figure has three straight lines pq qr rs with coordinates p 0 0 q 0 2 100 r 0 6 140 and s 0 8 130.

For the loading portions of the curves the higher the strain rate the larger the stress.

Where σ is the value of stress e is the elastic modulus of the material s ty is the tensile yield strength of the material and n is the strain hardening exponent of the material which.

Figure 5 shows the true stress true strain curves to εmax 1 0 at three different compression strain rates i e.